- Cedar Creek WPCP

- Bergen Point Wastewater Treatment

- Glen Cove WWTP

- Village of Greenport WPCP

- Barnes Avenue Sanitary Sewer Flow

- Center Moriches Business District

- Suffolk County Sewerage Capacity

- Massapequa Creek Preserve

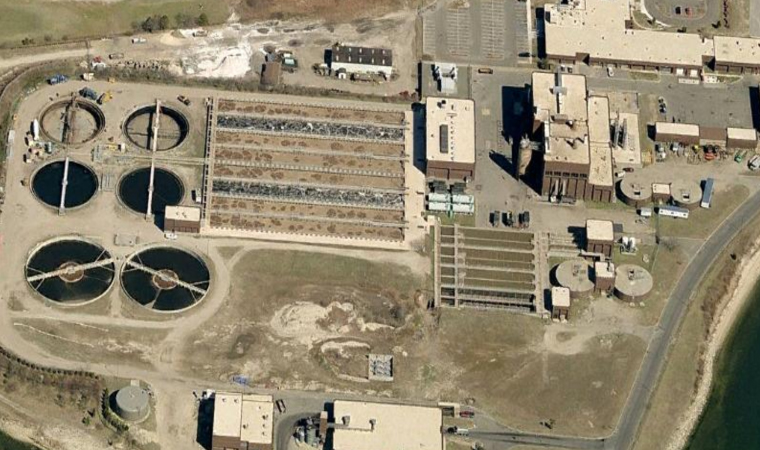

Cedar Creek WPCP

Wantagh, NY

Show Project Details

Cameron Engineering was retained by the County to provide supervisory personnel to work with County personnel at the Cedar Creek Water Pollution Control Plant, a 72 MGD secondary treatment facility. Due to vacancies caused by retirements from recent incentive plans and unfilled staff shortages, Cameron Engineering provided management personnel including a Grade 4A Operator to assume responsibility for the day to day oversight of the facility.

Cameron Engineering was able to provide stability in the supervisory role and worked with the County Operations and Maintenance departments to establish proper operational controls and to implement emergency repairs to equipment on a critical need basis. The facility has remained in compliance since our involvement. Cameron Engineering continues to provide technical assistance on operations and design assistance for capital planning initiatives such as influent and effluent screening projects.

Bergen Point Waste Water Treatment Plant Ultraviolet Light Disinfection

West Babylon, NY

Show Project Details

Suffolk County Department of Public Works (County) operates the Bergen Point Wastewater Treatment Plant (Bergen Point) that serves the Towns of Babylon, Islip and portions of Huntington. Bergen Point has a future design flow rate of 40 Million Gallons per Day (MGD), peak flow rate of 90 MGD and the facility treats approximately 600,000 gallons per day of scavenger waste. Hypochlorite has been the disinfection process since the plant was constructed in the late 1970’s. The County recognized that the use of hypochlorite as a disinfectant may produce byproducts that could harm the environment.

The County initiated the disinfection project to determine available alternatives to hypochlorite. The Feasibility Study extensively evaluated many disinfection alternatives. A detailed evaluation was performed for ultraviolet light and sodium hypochlorite/sodium bisulfite alternatives, including design criteria, system description, layout and costs. It was recommended that the County was best served by implementing an ultraviolet disinfection system, thereby eliminating concern for the generation of harmful byproduct.

Design of the ultraviolet (UV) light disinfection system included an extensive hydraulic analysis of existing Plant flows, as the UV System was installed in-line with the existing 108” Plant Effluent pipe. The UV System has the capacity to treat 120 MGD at 54% ultraviolet light transmittance (% UVT) and/or 90 MGD at 45% UVT. The UV System Reactor measures 55’ x 60’ x 18’ deep to accommodate existing hydraulics and to provide for four (4) UV channels each measuring approximately 30’ long x 8’ wide x 4’ deep. Each UV channel is equipped with two (2) UV banks with 32 modules per bank and eight (8) low pressure-high intensity UV lamps per module, for a total of 2,048 UV lamps. A climate controlled UV control building and 750 kW generator was provided to house the System Controls and spare parts (i.e., bulbs) storage, and to provide for dedicated backup emergency power to the UV Facility. The UV System is in successful commercial operation with construction of a Pre-Engineered Metal Building (also designed by Cameron Engineering) to house the entire UV System currently in progress.

In addition to design of the UV System design, the Contract Documents also included extensive vibration monitoring, American Recovery and Reinvestment Act funding compliance, bypass pumping of up to 110 MGD, dewatering, and extensive experience requirements for the ultraviolet disinfection manufacturer, including a 5-year maintenance agreement and lifetime UV System performance guarantee. The proposed facility is located adjacent to existing wetlands, requiring extensive coordination with the NYSDEC for wetlands permitting.

This project won the 2015 ACEC Engineering Excellence Award – Gold.

Glen Cove WWTP

Glen Cove, NY

Show Project Details

The City contracted Cameron Engineering to design for the installation of a biological nutrient removal (BNR) system at the City’s 8.0 MGD Water Pollution Control Plant. The City has taken the lead in addressing reduction of nitrogen in its effluent with assistance of a State Bond Act Grant of $3.4M. The City modified the aeration tanks by creating both anoxic and oxic zones for use of the Modified Ludzack Ettinger nitrogen reduction process. The aerators are equipped with submerged mixers and a fine pore aeration system. Existing screw pumps were incorporated into the nitrate return system. In addition to the BNR system, facility improvements included replacement of the influent bar screens, belt filter press feed pump controllers, rebuilding of influent and RAS pumps among other plant upgrades. A new blower with D.O. feedback was included for which the City received a $250,000 rebate from the local power authority.

Construction management and installation of biological nutrient removal (BNR) technologies requiring retrofit of eight (8) aeration tanks with fine pore aeration system. The project included concrete and membrane bafflewalls, new 550 hp blower with automatic dissolved oxygen control, rehabilitation of 30 sludge gates, new motor control centers and 24 submerged mixers. Plant now meeting 2014 levels for nitrogen reduction.

Village of Greenport WPCP – Phase II BNR Upgrade Design

Greenport, NY

Show Project Details

The Village of Greenport is a small modest income community of 2,500 residents located on the eastern end of the North Fork of Long Island. The Village owns and operates a 650,000 gallon per day wastewater treatment plant that was originally constructed in the early 1940s as a primary treatment facility. The treated effluent of the facility is discharged into Long Island Sound. The facility was upgraded to provide secondary treatment in the mid- 1970s with the addition of aerated lagoons. The Village was faced with ever increasing water quality regulations imposed by both the Federal and State regulatory agencies to reduce the nitrogen loading to the Long Island Sound from the plant’s discharge.

The Village engaged the Firm to develop a cost effective plan for reducing the nitrogen loading from its aged facility and reduce its total residual chlorine (TRC). The cost associated with the construction a new tertiary treatment facility was a financial challenge for the Village and its residents. The Firm working with the Village developed a plan that would incorporate an innovative treatment process for Biological Nutrient Reduction (BNR) and incorporate more than fifty (50%) of the existing plant infrastructure.

This approach provided the Village with an efficient state-of-the-art treatment process while reducing overall capital cost by reusing existing structures in the new treatment process train. The heart of the upgrade centered on an innovative biological nitrogen reduction (BNR) technology featuring the Integrated Fixed Film and Activated Sludge (IFAS) process. The Firm assisted the Village in securing a $200,000 grant from the New York State Energy Research Development Agency (NYSERDA) to perform pilot testing of this technology. Pilot testing demonstrated the capability of the IFAS system to meet the challenge of nitrogen reduction in a cost efficient manner.

In addition to the BNR process, the facility features ultraviolet light disinfection that replaced the former sodium hypochlorite disinfection system. The elimination of chlorine in the discharge is a benefit to the local marine environment. The incorporation of this new technology with reuse of existing tankage and piping was not without its challenges.

The $6.5 M Phase II BNR/UV upgrade project has resulted in reducing the Village’s nitrogen discharge by 90% more than exceeding the stringent regulatory requirement of 80%. The project also received over $4M in ARRA, CDBG, NYSEFC, NYSERDA and Small Community grants with the balance of the funding coming in the form of a 0% loan from the NYSEFC. The project has exceeded the Village’s expectations and has moved the Village’s plant from one of the worst performing facilities to one of the best performing on Long Island.

Barnes Avenue Sanitary Sewer Flow Overflow Study

Baldwin, NY

Show Project Details

Cameron Engineering was engaged by the County of Nassau Department of Public Works to conduct an evaluation of the sewer system in the unincorporated area of Baldwin. The sewer system and in particular the interceptor (2T-4) running north to south had experienced periodic sanitary sewer overflows (SSO) during severe rainfall events. Superstorm Sandy’s surge resulted in an SSO occurrence that prompted the study. In the study, modeling and flow metering efforts resulted in confirmation of the likely causes of the SSOs. A recommended solution was to consider flow diversion from collection systems located north of Baldwin (Village of Hempstead) and redirect the sewage to the east and thus reducing the flow through Baldwin. Additional improvements to the Parsonage Creek Siphon and collection system could result in improved flow conditions and reduce the potential for SSOs. The County contracted with Cameron Engineering to design the flow diversion improvements that include a new pump station and force mains to transfer flow to the County’s Cedar Creek WPCP.

Specific tasks included:

- Flow monitoring in Baldwin

- Development of a working hydraulic model

- Identification of options for reducing SSOs

- Design of new flow diversion pump station and force mains

- Design of improvements at Parsonage Creek Siphon and downstream gravity mains

- Construction related services

- Startup and O&M services

Center Moriches Business District Sewering Feasibility Study

Center Moriches, NY

Show Project Details

Cameron Engineering was awarded a contract to develop recommendations for sewering the Center Moriches study area. Cameron Engineering evaluated three possible alternatives:

- Site a new WWTP that would accept all the wastewater flows from the study area.

- Send all of the study area flows to either proposed or existing nearby treatment plant(s)

- Create a smaller new WWTP to accept a portion of the study area flows while sending the remaining part of the study area flows to either proposed or existing nearby treatments plants

Center Moriches Business District is located in the center-south quadrant of the County in the southeast portion of the Town of Brookhaven (0.31 square miles). In addition to existing commercial and business establishments, the area includes a number of strip shopping centers and vacant areas that can be developed for revitalization, workforce housing, and associated development in the vicinity of the railroad station. The area also has existing onsite systems that have the potential for underflow going to Mud Creek, Senix Creek, Areskonk Creek, and Orchard Neck Creek, all of which discharge to Moriches Bay.

Selection of a wastewater treatment plant’s (WWTP) location was complex due to high groundwater level in the area and potential distance from the service area. Cameron Engineering reviewed Suffolk County Water Authority’s data and other available information to estimate present and future wastewater flows.

Cameron Engineering also evaluated the wastewater flow and corresponding costs and made recommendations on the feasibility of adding to the study area the following parcels:

- William Floyd Middle School – 630 Middle Island Road, Moriches, NY

- Center Moriches High School – 311 Frowein Road, Center Moriches, NY

- Knights of Columbus – 313 Frowein Road, Center Moriches, NY

- Our Lady Queen of Apostles Regional School – 2 St. John’s Pl., Center Moriches, NY

Feasibility Reports for Existing Sewerage Capacity

Suffolk County, NY

Show Project Details

Cameron Engineering was awarded a contract to provide feasibility reports for eleven (11) critical areas that include an evaluation of existing sewerage facility infrastructure and to develop a project on sewering a limited number of critical areas of need within the County. The existing sewered areas include Patchogue, Port Jefferson, Sag Harbor, and Riverhead/Calverton.

Additionally, the Town Planning Department considered expanding Business District J-6 to this area to promote Smart Growth development. Due to the Study Area’s proximity to the County’s Sewer District No. 1 (Port Jefferson) which is part of the CP8185 study, a preliminary evaluation on sewering needs was conducted by Cameron Engineering. The initial evaluation yielded information that the projected flow exceeds the available capacity available at SD No. 1 facility. It was necessary to conduct a more detailed Feasibility Study to analyze the factors associated with the sewering of a specific area. That study is currently on-going (Jan 2015).

The County has been evaluating a number of study areas throughout the County for feasibility of sewering. Cameron Engineering has performed a number of these Feasibility Studies that investigates a number of critical items that are associated with sewering of a specific area. A Feasibility Study is required to ascertain the needs of the study area, the environmental, social and economic impacts, the sizing and siting of facility, the costs (capital and O&M) and legal requirements for forming a district among other key issues.

Restoration of Massapequa Creek Preserve

Massapequa, NY

Show Project Details

The installation of sanitary sewers and increase in groundwater withdrawals for public water consumption lowered groundwater elevations in the 423-acre Massapequa Preserve. Streamflow was reduced and water levels lowered in the four ponds and two lakes. Designs were created to mitigate the effects of lowered groundwater by augmenting streamflow, making improvements to the streams and ponds, and better managing stormwater. A 1,100 gpm streamflow augmentation system was designed to bring groundwater to the upper portion of the stream channel. Stream bank stabilization designs included branch packing, live stakes, fascines, degradable geotextiles and native plantings. New berms in the ponds separate stormwater from cooler baseflow. Drainage swales divert stormwater from the ponds to the red maple swamp for stormwater treatment, recharge, irrigation, and swamp preservation. End-of-pipe treatment units remove stormwater sediments and contaminants. The improvements benefit the wetlands and stream channel of the preserve, water discharged to the South Shore Estuary. Cameron Engineering prepared a Draft EIS, a Final EIS and a successful Clean Air/Clean Water Bond Act grant for $1,300,000.

This project received the ACEC NY 2012 Gold Award for Engineering Excellence.