Awards 2022

2022 ACEC NY Engineering Excellence – Diamond

Featured Award

FDNY Training Academy Live-Fire Training Building

The Training Academy is a world-class training center serving hundreds of recruits per year as well as outside agencies and personnel from other municipalities across the country and world. In addition to classroom instruction, the Academy uses live-fire training buildings. The goal of the project was to replace a training building with a state-of-the-art live fire multistory apartment replica with the capacity to activate live Class ‘A’ and Class ‘B’ fires that could be extinguished and quickly reset for training. The firm completed mechanical, electrical, structural, and civil engineering services. The Live Fire Training Aid prepares the firefighters for real life situations driving home the meaning of the quote, “Let no man’s ghost come back to say, “my training let me down”.”

Using special protective fire tiles, the structure can sustain repetitive burns. It has strategically located training stations and a floor design that drains fire-hose discharge. Additionally, the building has an integrated temperature monitoring system that instructors can use to monitor and control the conditions of the training exercises.

During the design process, a propane piping system was incorporated to feed a fixture that simulates a live sofa/furniture fire and flashover, which has a remote simulator control system for precise control.

An advanced ventilation system was added to quickly exhaust the smoke from throughout the building to maintain safe conditions during exercises and decrease the reset time between exercises within the building.

In addition, the property is located within a flood zone, so all the vital equipment and training spaces were located above the base flood elevation and freeboard, and a raised platform was created to provide additional training and adjudicating surfaces.

The project contributes to the safety and security of the citizens of NYC as the facility prepares the firefighters for real situations that will help save lives and property.

Economic benefits include the on-the-job training for firefighters and provides ongoing social benefits that the FDNY provides to New York City. Sustainable development considerations include utilizing propane to simulate the fires, which is cleaner burning, and recycling of the water so water waste is minimized.

The building was designed to have materials combusted within it for live-fire training exercises without damaging the structure. The structure was designed on piles due to poor soils conditions. The walls, ceilings and floor elements had to have special fire-proof tiles installed on them to protect the structure sudden changes in temperature upon extinguishing fires.

Located on an active FDNY training academy property, the design and construction had to keep safety as a priority and safety bollards were included into the final design of the structure to protect those training from the actively moving fire vehicles. The property is also located on an isolated island, where flooding is a concern.

The project successfully met and exceeded the FDNY’s requirements that included providing a fire resistant building construction, ensuring proper drainage, simulating multiple styles of construction typical of NYC, incorporating safety protocols, protection of simulator controls from fire, water and heat, and providing long-term stability of interior facilities and structural stability.

2022 ACEC NY Engineering Excellence – Platinum

Featured Award

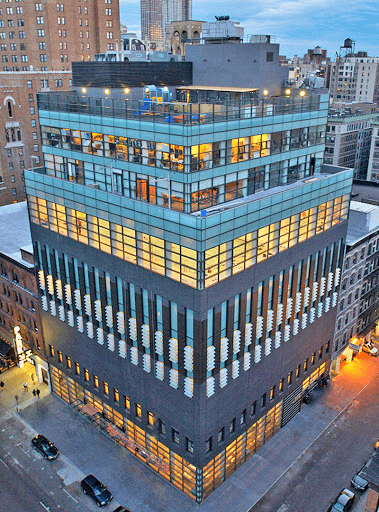

Needlepoint Bipolar Ionization System Engineering Services for Mastercard Tech Hub

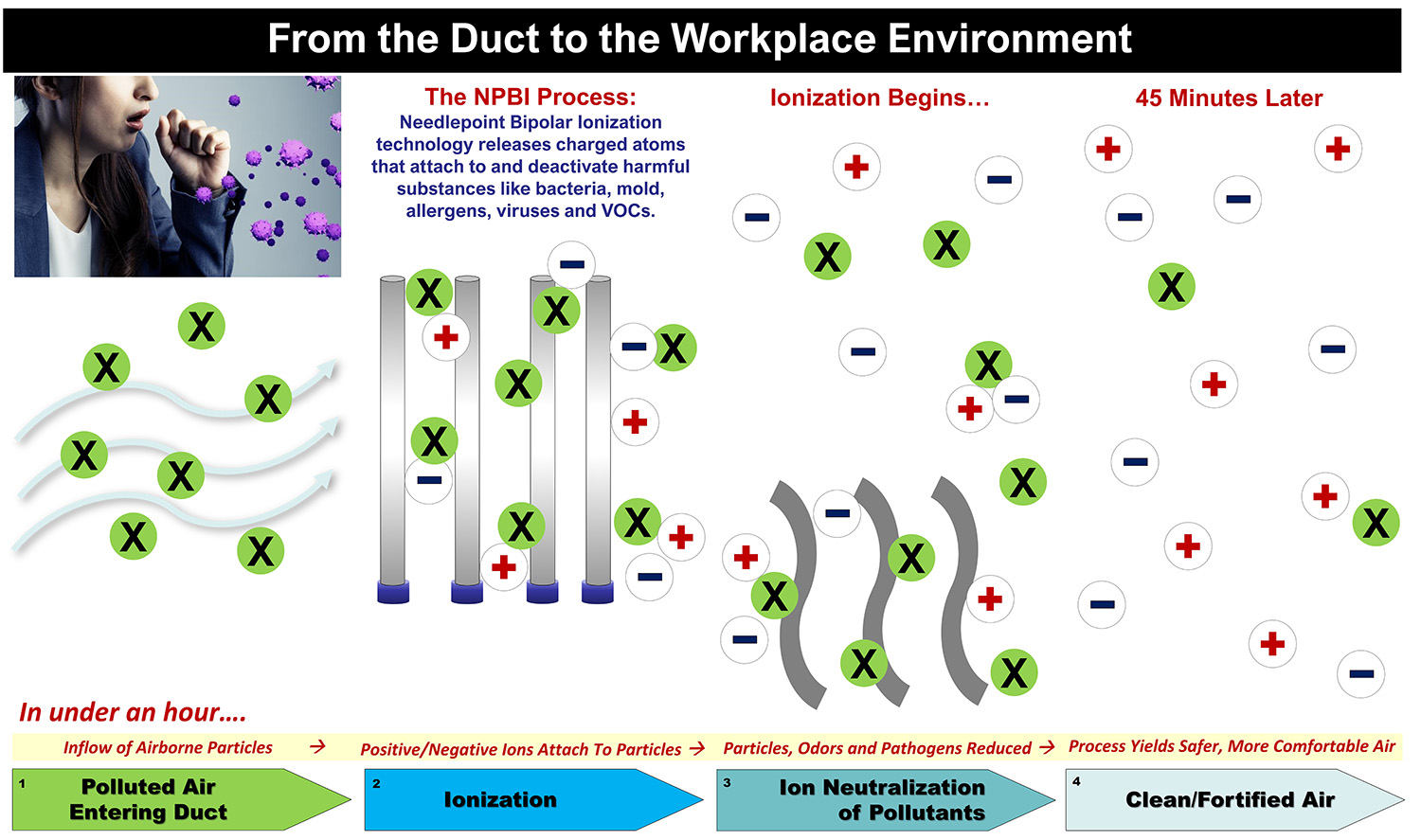

The world has been concerned about pathogens that can easily spread from person to person. Viral spread is linked to the presence of fine particles and contaminants in a building. For creating a safe and healthy indoor environment, it makes sense to find ways to help minimize viral spread by reducing the number of indoor air contaminants.

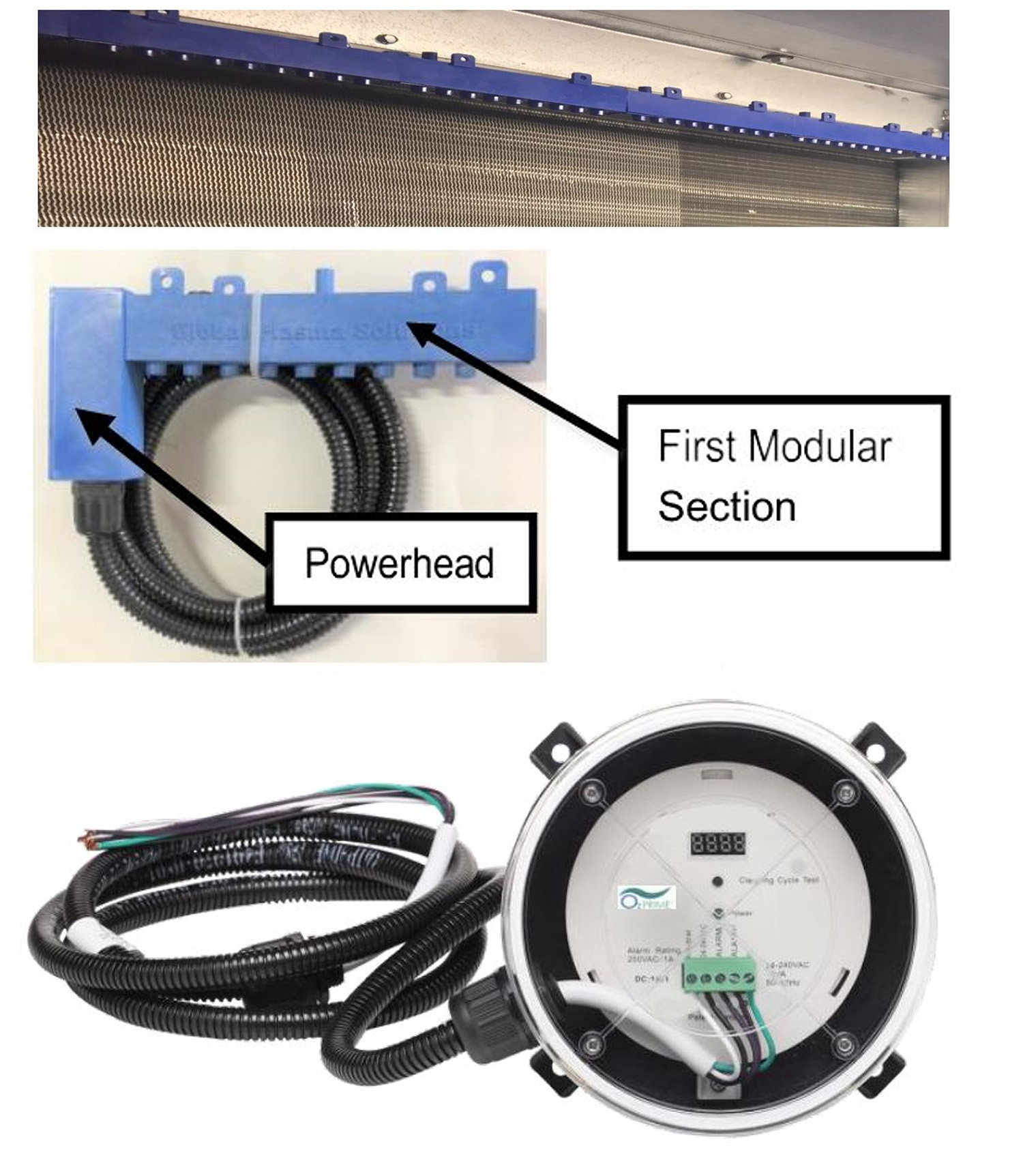

The installation of a Needlepoint Bipolar Ionization (NPBI) system helps facility operators enhance the air quality in their buildings using their building’s existing air handling systems. This saves money, time, and energy while increasing the cleanliness and safety of the air the occupants breathe. Positive and negative ions help to agglomerate fine sub-micron particles, making them filterable. The ions also kill pathogens and improve indoor air quality by reducing and controlling harmful pathogens, viruses, bacteria, and certain volatile organic compounds (VOCs).

Out of many available Virus Deactivating Technologies, such as Media Filtration, Ultraviolent Lighting, and Electronic Air Cleaners, Needlepoint Bipolar Ionization is one of the most effective technologies that can be retrofitted into the existing HVAC Systems without a significant increase in power consumption and pressure drop.

This process effectively deactivates bacteria and viruses, reduces odors, VOCs, and particulates without producing Ozone or any chemical byproduct other than water vapor.

Bipolar ionization does not require expensive equipment upgrades and much higher energy usage.

Recent advances have made bipolar ionization units cheaper and easier to install. They can help actively and continuously clean, disinfect and decontaminate the indoor air without a substantial increase in building’s energy usage and avoid costly upgrades to the existing HVAC systems.

The Siemen’s NPBI solution has provided promising test results of their technologies’ efficacy against viruses and bacteria, yet we emphasize the importance of a holistic approach when it comes to infection prevention as there is no single solution today that is 100% effective in removing all contaminants.

As the country shapes a new normal in the wake of the pandemic, improving occupational safety and health should be a priority, especially in poorly ventilated indoor spaces.

As buildings become more energy-efficient, they are less likely to circulate fresh, clean air and more likely to accumulate unsafe levels of particles, bacteria, mold spores, and VOCs. The possibility of aerosolized spread of COVID-19 and the ability of particles to hang in the air for extended periods of time would make the consideration of an active air-cleaning strategy even more prudent.

To make the designed system effective against most viruses, including Covid-19, a suitable bipolar ionization device was specified and designed to be placed in optimum locations in the air stream to achieve the number of ions defined in the system design criteria for optimum air cleaning.

The indoor air quality improvement has been verified with particulate sampling by a third-party testing company.

With NPBI installed at 150 Fifth Ave, the building’s mechanical systems now create a safe and healthy indoor environment, reducing the health risks to employees and building occupants by reducing the spread of airborne and surface contaminants.

2022 ACEC NY Engineering Excellence – Gold

Featured Award

NYCHA Rental Assistance Demonstration (RAD) Expanded Bundle III

Rental Assistance Demonstration (RAD) is a component of NextGeneration NYCHA, NYCHA’s 10-year strategic plan to preserve public housing, get NYCHA’s financial house in order and become a more effective and efficient landlord.

The firm provided the design of mechanical, electrical, plumbing (M/E/P), sprinkler, fire alarm (FA), and structural systems. The project involved the renovation of approximately 1315 apartments units totaling over 1.73M gross sq. ft. of space, across 60 buildings. The renovations featured upgrades to apartments, base building services, public spaces, and community/public assembly spaces that included a daycare center.

The project included coupling a high efficiency boiler with a plate and frame heat exchanger, connected to a 200-gallon storage tank for. This would allow for the lowest usage cost during peak times when the domestic hot water storage tank could be utilized. The condensing boiler is approximately 97% more efficient than the traditional gas fired hot water tanks, and by coupling this with circulating pumps for both hot water heating and domestic hot water, buildings can employ the storage tank water during peak hours, and utilizing the same system, supply perimeter heating during the winter months.

The incorporation of modernized building systems was developed with “over the air” ethernet controls to give ownership the capability to review and respond to any codes that the boiler system can provide. Within the apartment scope of work, special attention was given to the indoor air quality control. This would also assist with the guidelines to ensure that mold, pollen and asthma-triggering materials are lessened for the welfare of the occupants. The modification and renovations included energy star appliances, as outlined by the 2015 Enterprise Green Community criteria.

Central battery inverters were introduced to lessen the load of the diesel fired generators. This allowed for less carbon emissions throughout these buildings and assisted with monthly testing of the generators.

The investment will appreciate overtime and provides the Owner with instant value for their dollars.

The client and the future occupants will benefit by enjoying a properly conditioned space while experiencing the reduction of energy use not previously available in the building.

The energy savings provided by the building management will reduce operational costs and the impact the building will have on the local utility grid.

By far, the biggest challenge is working in occupied buildings and being constantly aware of occupants during each stage of the project.

This project successfully addressed the complex criteria of creating technologically functional apartments that comply with and, in some cases, exceed New York City Code, NYCHA design guidelines, Enterprise Green Community Criteria, and the Developer’s guidelines.

The design created useful spaces making it an economical and cost-effective solution for the client. The project met the client’s goal to immediately accommodate the project requirements while also providing for energy savings and technological advances with M/E/P controls.

The project was slightly over budget due to market and timeline delays cause by the pandemic but was able to meet the vast majority of the substantial completion dates.

2022 ACEC NY Engineering Excellence – Gold

Featured Award

Water Quality Improvements at Gerry Park (Formerly Roslyn Pond Park)

Gerry Park, located in the Historic District of the Village of Roslyn, New York includes an interconnected series of three freshwater ponds, Upper Pond, Middle Pond and Lower Pond. The ponds receive stormwater runoff from the surrounding 340-acre watershed area. The Upper Pond discharges to the Middle Pond, which subsequently discharges to the Lower Pond, with final discharge through a culvert to an intertidal waterbody.

Years of sediment laden stormwater runoff had elevated the sediment level of the Pond System, severely limiting its stormwater retention capacity, contributing to warmer water temperatures, and decreases in dissolved oxygen concentrations. The sediment loading had decreased wildlife habitat and species diversity and promoted the growth of invasive species. Waterfowl added to the high nutrient loading causing algal blooms.

The firm implemented a water quality management plan that involved removing excess sediments, providing for the capture of stormwater driven sediments and debris, and enhancing the historic Park’s recreational and aesthetic characteristics.

Subconsultants included Jerry P. Larue L.S. P.C. (land surveying) and AK Associates (topographic survey).

The Town wanted the Park to remain open to the public thereby limiting the area available to the Contractor for temporarily staging dredge spoils. The use of “geotubes” for the receipt and dewatering of the dredge spoils allowed for limited production of odors and a reduction of space required for typical placement, storage and drying of dredge spoils.

Creating wetlands, removing invasive vegetation and opening up visual corridors within the Park resulted in public understanding and support of the Project.

Restoring depth and volume to the ponds increased the overall health and aesthetics of the Park allowing visitors to enjoy the natural beauty of the Park by observing the new plantings. Dredging the sediment load from the Ponds increased detention time for stormwater treatment. Chambers that were provided to capture and remove sediments and debris, now remove pollutants that degrade the environment and aesthetics of this public resource.

The engineering design had to incorporate the Park’s natural features and improvements had to be installed in an unobtrusive manner. The project involved extraordinary challenges as the Park has known historic significance, and therefore no significant visual or physical changes to the Park were permitted. This was difficult because the project site is an open air passive public park offering an abundance of natural elements such as trees, which had to be protected with limited removal of same.

Additionally, the Project was constructed during the height of the pandemic where the implementation of CDC guidelines imposed an additional level of challenges. Even with the heightened restrictions, the project was completed on schedule.

The firm provided daily insight and coordination resulting in successfully accomplishing the goals of the project. The firm’s design aided the Town in their pursuit of several grant opportunities and the Town was able to secure grant funding to significantly offset the cost to the Town. The Project was completed on time and on budget.

Awards 2021

2021 ACEC NY Engineering Excellence – Diamond

Featured Award

Ronkonkoma Hub Sanitary Pump Station and Force Main Piping

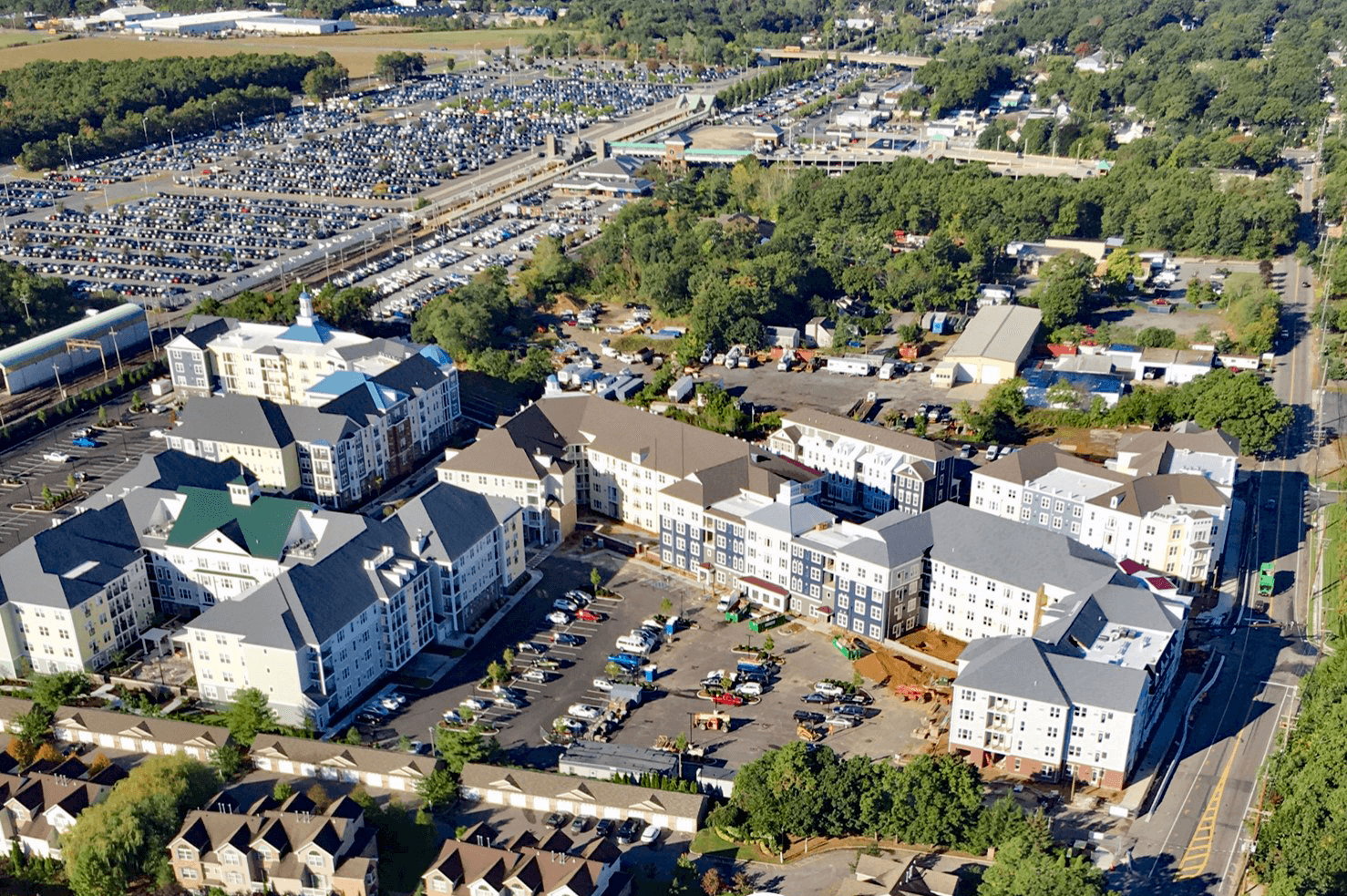

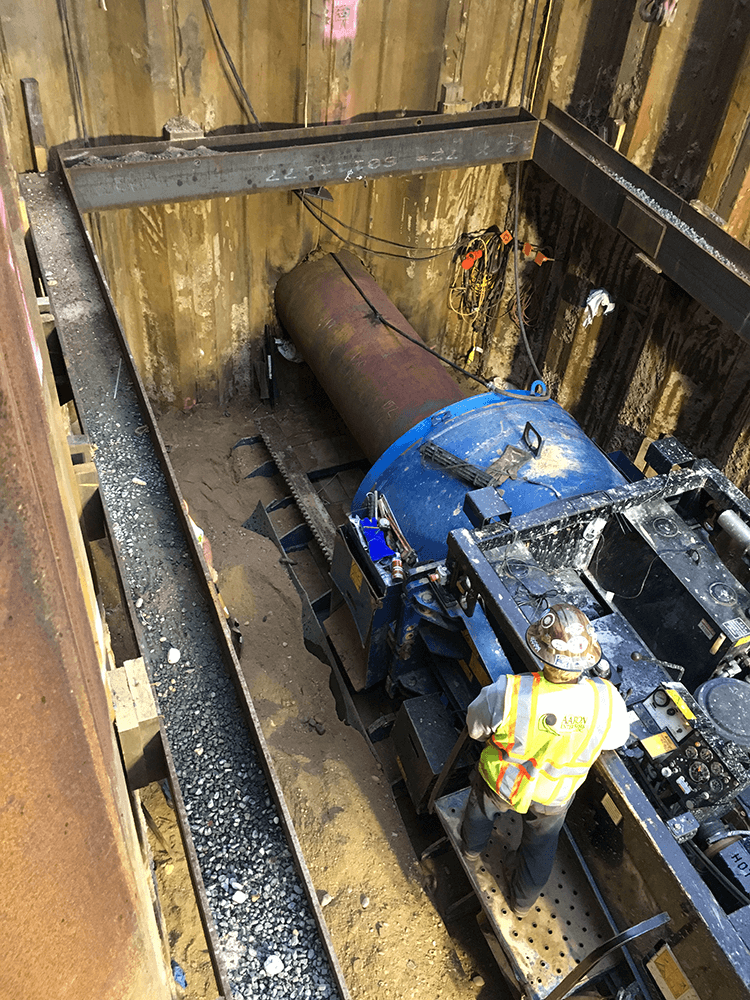

The County engaged Cameron Engineering to initiate the design of a 2.3 MGD Pump Stations and associated force main and gravity piping for the Transit Oriented Development (TOD) called the Ronkonkoma Hub. Cameron Engineering designed a new sewage Pump Station and Force Main to transfer the wastewater generated by the TOD to the County’s sewage collection system that flows to the Bergen Point Sewage Treatment Plant. The closest connection point was located seven miles away. This required a 5.5-mile dual force main and a 1.5-mile gravity interceptor.

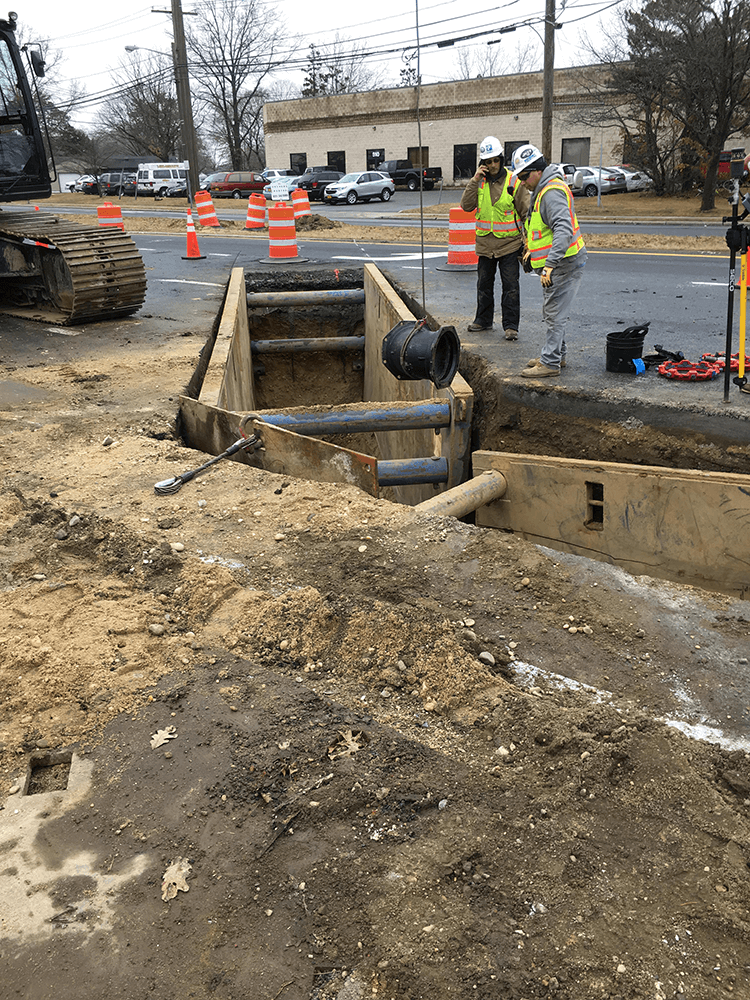

What seemed like an impossible task turned out to be an ingenious way to provide sewer services to a growing TOD in the heart of Long Island. The initial design provided for jacking of a larger diameter ductile iron pipe to serve as a conduit/casing for the section of the two force main pipes passing under the headwaters of the Connetquot River an environmentally sensitive location. Due to a significant change (rise) in groundwater elevation at this location, it was determined that significant dewatering would need to occur to provide the lower groundwater levels necessary for stable working conditions for the excavation required for the installation of the force mains.

The creative solution determined by County, Contractor and the Firm’s representatives included the “open cut” installation of the force main piping within a concrete encasement through this area; design of a groundwater dewatering system to discharge to both the adjacent Lakeland County Park and to the completed downstream force mains to allow conveyance to the Bergen Point STP. The dewatering operation was required to provide for real time monitoring of the dewatering flow and turbidity concentrations to protect the downstream historic trout fish hatchery.

2021 ACEC NY Engineering Excellence – Gold

Featured Award

Wellbridge Addiction Treatment and Research Center

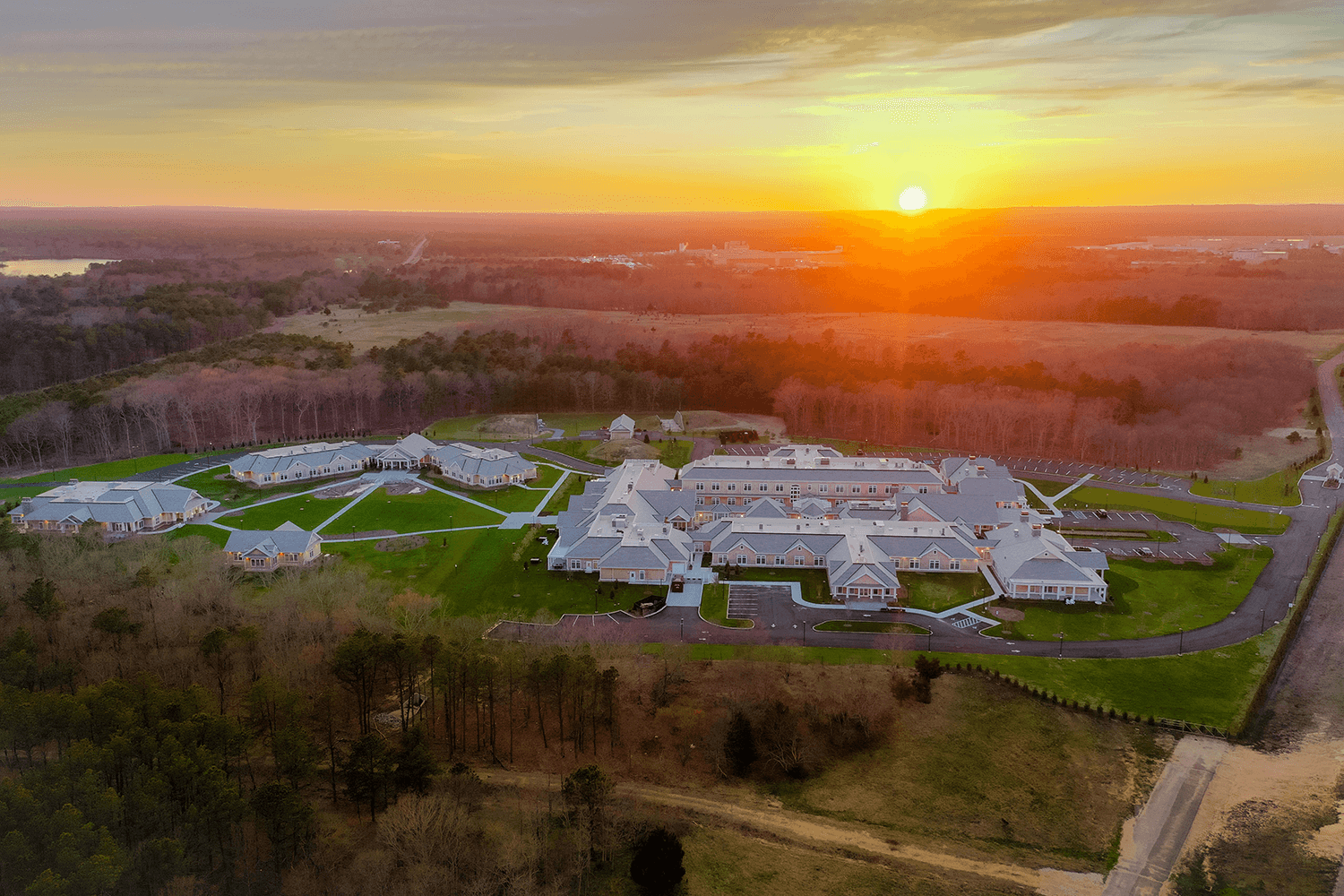

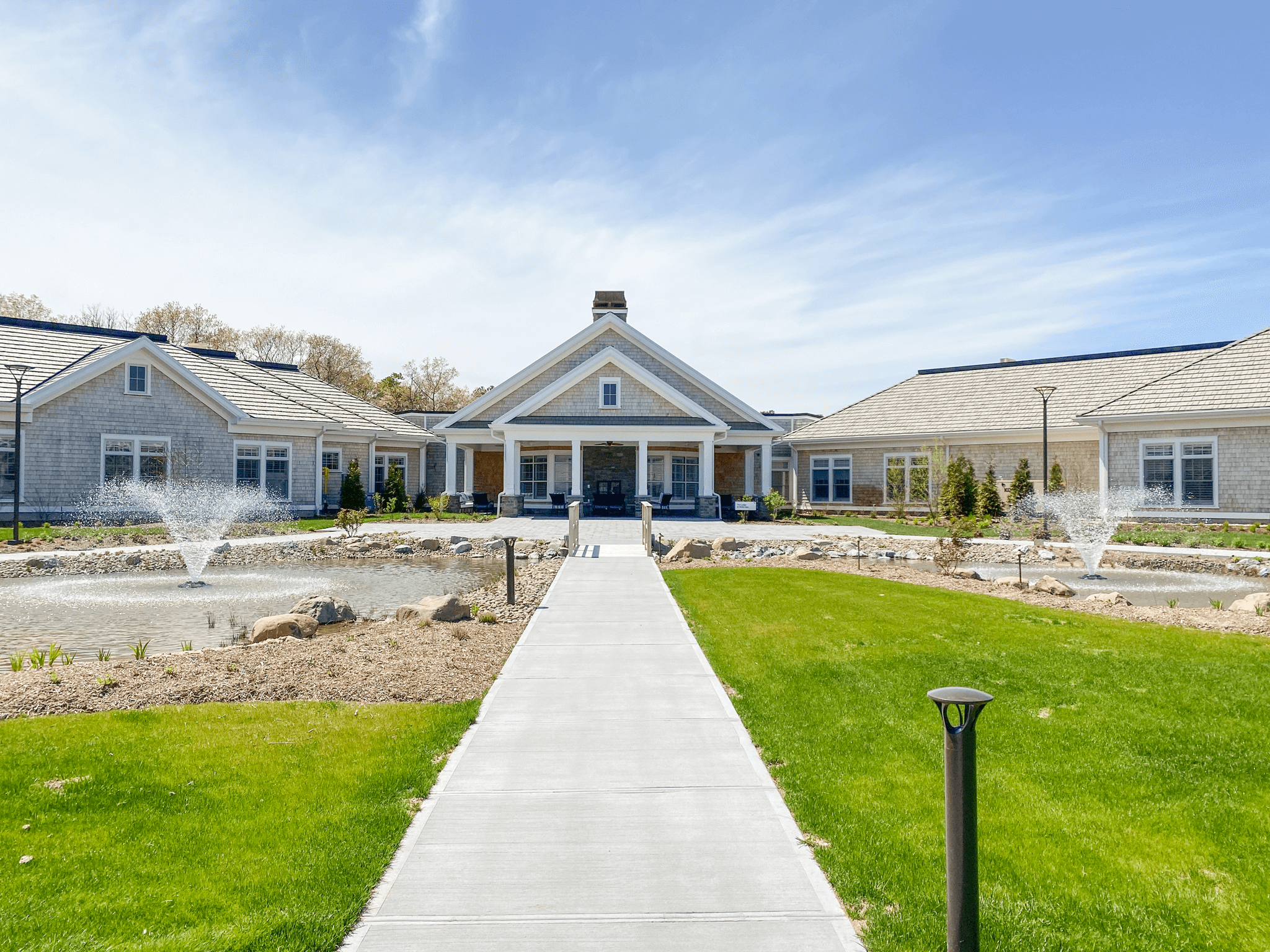

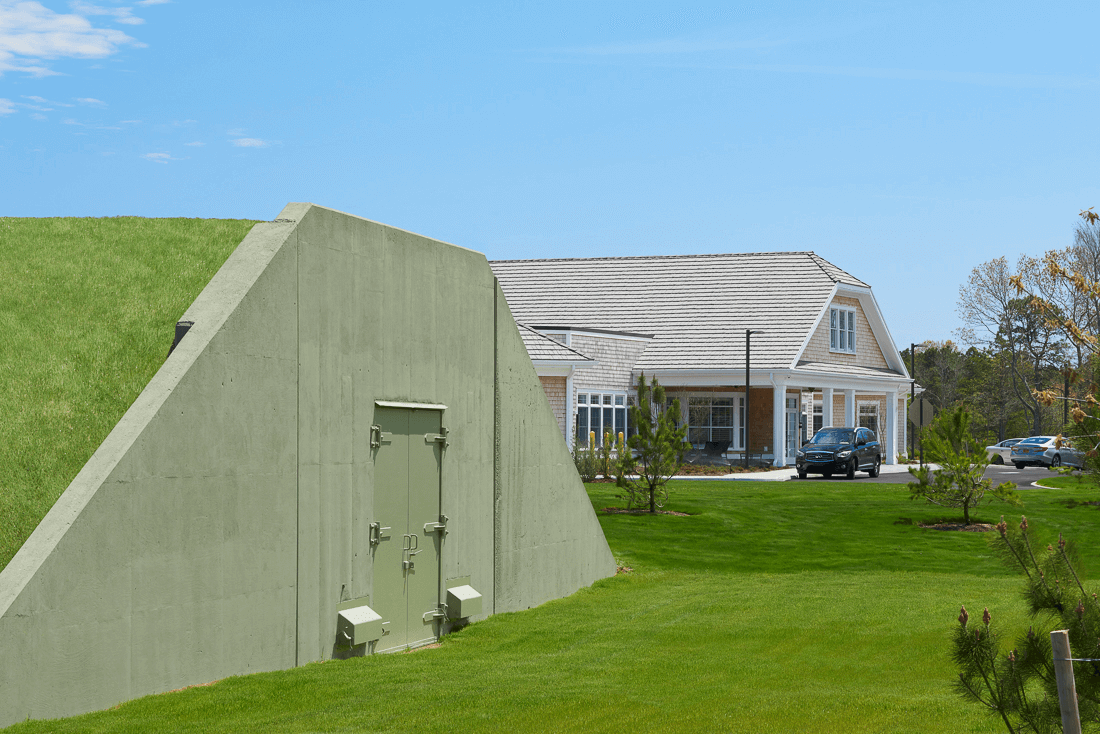

The 96-acre Wellbridge campus is a groundbreaking research and addiction treatment center established on the principles that the treatment of addiction, like any chronic disease, must be based on scientific evidence, directed by evolving needs of the patient, delivered in an environment that fosters well-being and compassionate care, and informed by the promise to continually advance.

Cameron Engineering’s scope of work initiated with the master planning of the entire Wellbridge campus. With a development program defined and conceptual architectural building footprints provided, a site master plan was formulated with critical engineering tasks focused on the overall development footprint, siting of the campus buildings, vehicular access, circulation and parking management, utility infrastructure demands, stormwater management approach, and open space amenity layout.

Optimizing “low impact development” (LID) strategies including compact development footprint, development within previously disturbed areas of the property, and use of natural topography and green infrastructure techniques to manage stormwater runoff. Irrigation water usage reduced by over 80% with native grasses not requiring irrigation and limited managed landscape areas.

A compact campus layout within the previously cleared and disturbed area of the 96-acre property to maximize the preservation of native woodlands and grasslands. Approximately 75% of the property (72-acres) will remain undisturbed and approximately 53% of the property (51-acres) will remain natural woodlands, grasslands and wetlands.

Wellbridge exemplifies how integral the engineering profession is to be contributing to a such an important social cause, while advancing economic growth in an environmentally sustainable manner. Wellbridge has brought immediate accolades to the engineering profession as publicly documented by the medical and science community, local civic leaders, business leaders and elected officials.

2021 ACEC NY Engineering Excellence – Gold

Featured Award

FDNY Training Academy Wharf Restoration

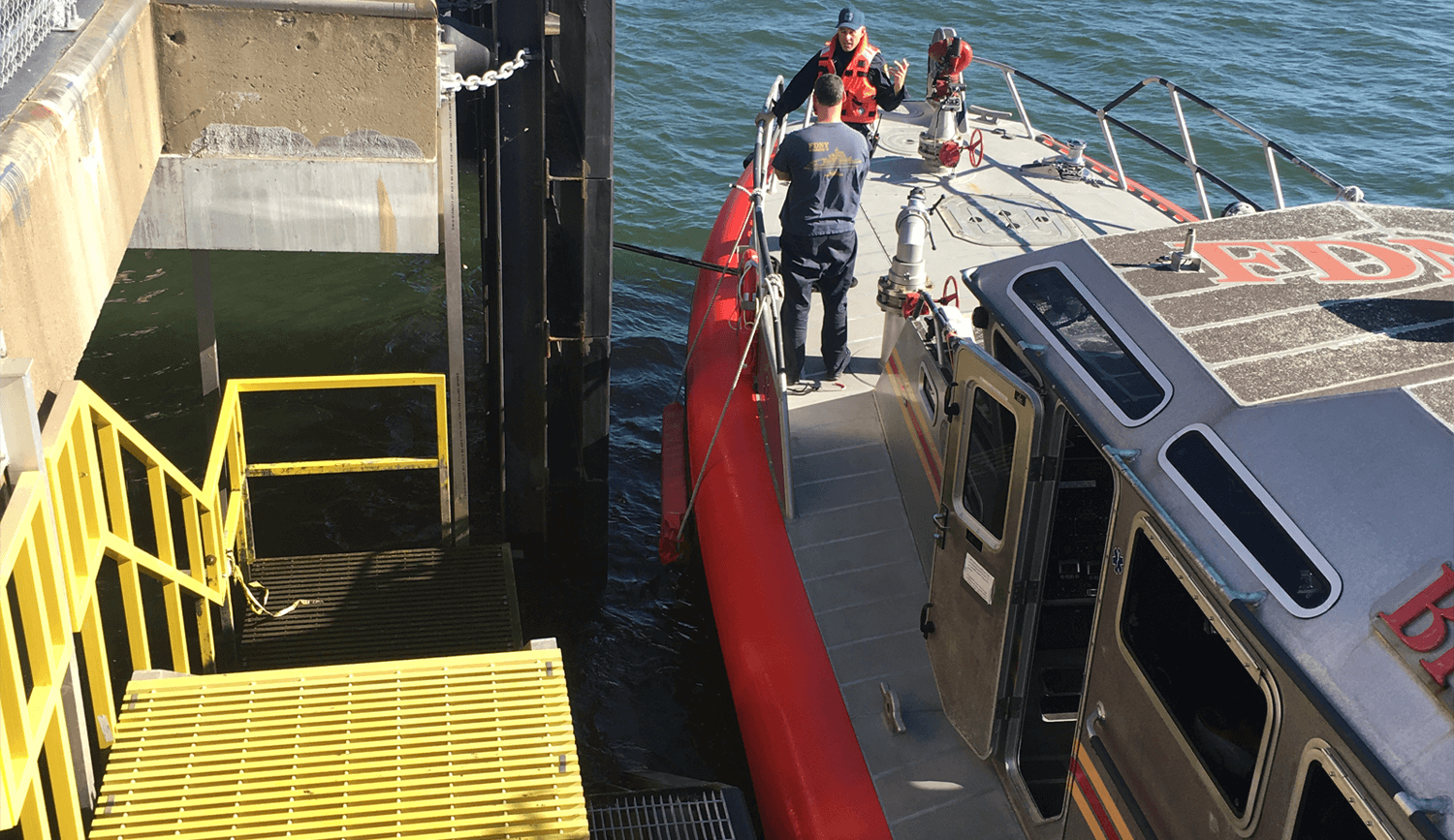

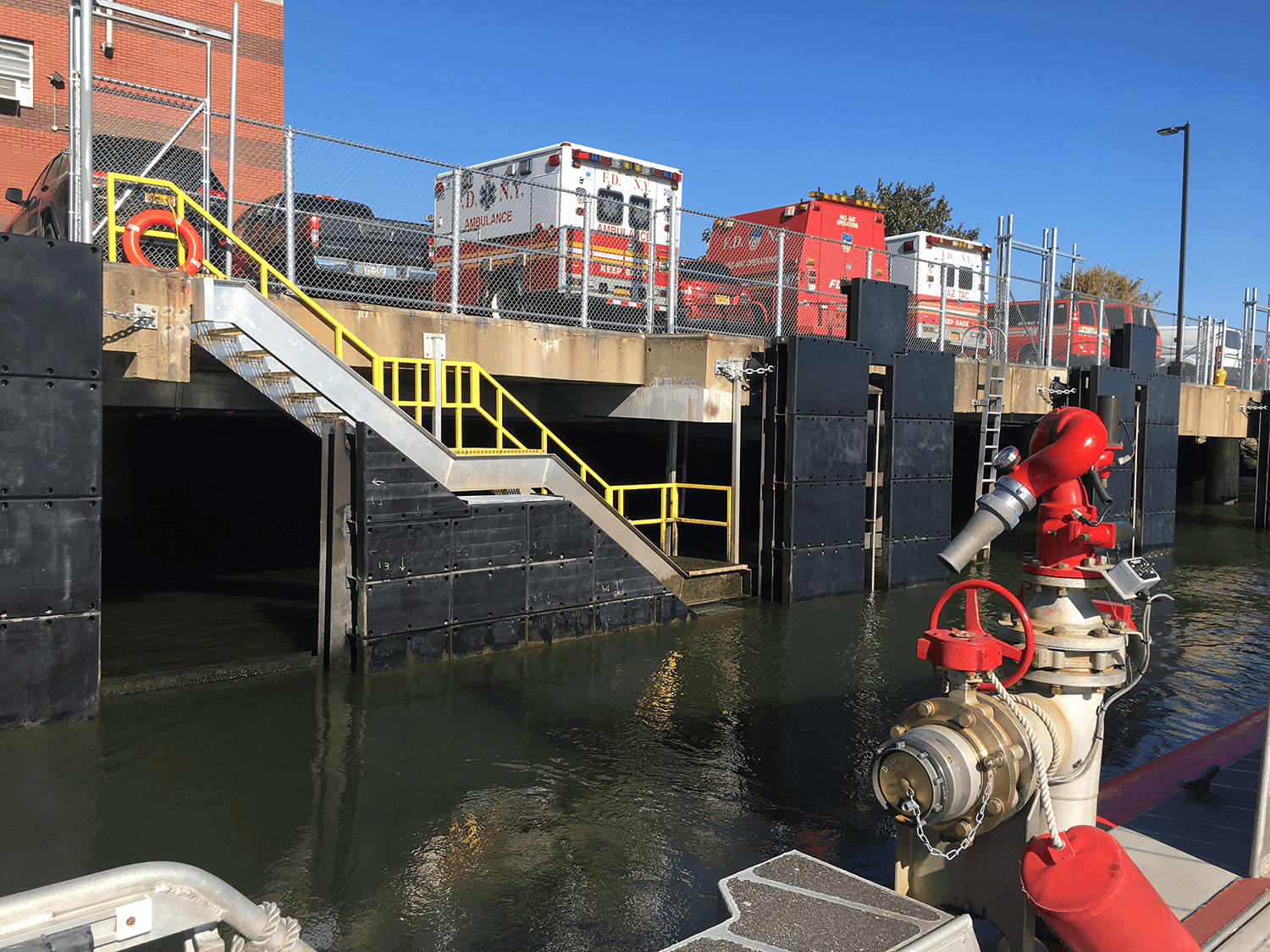

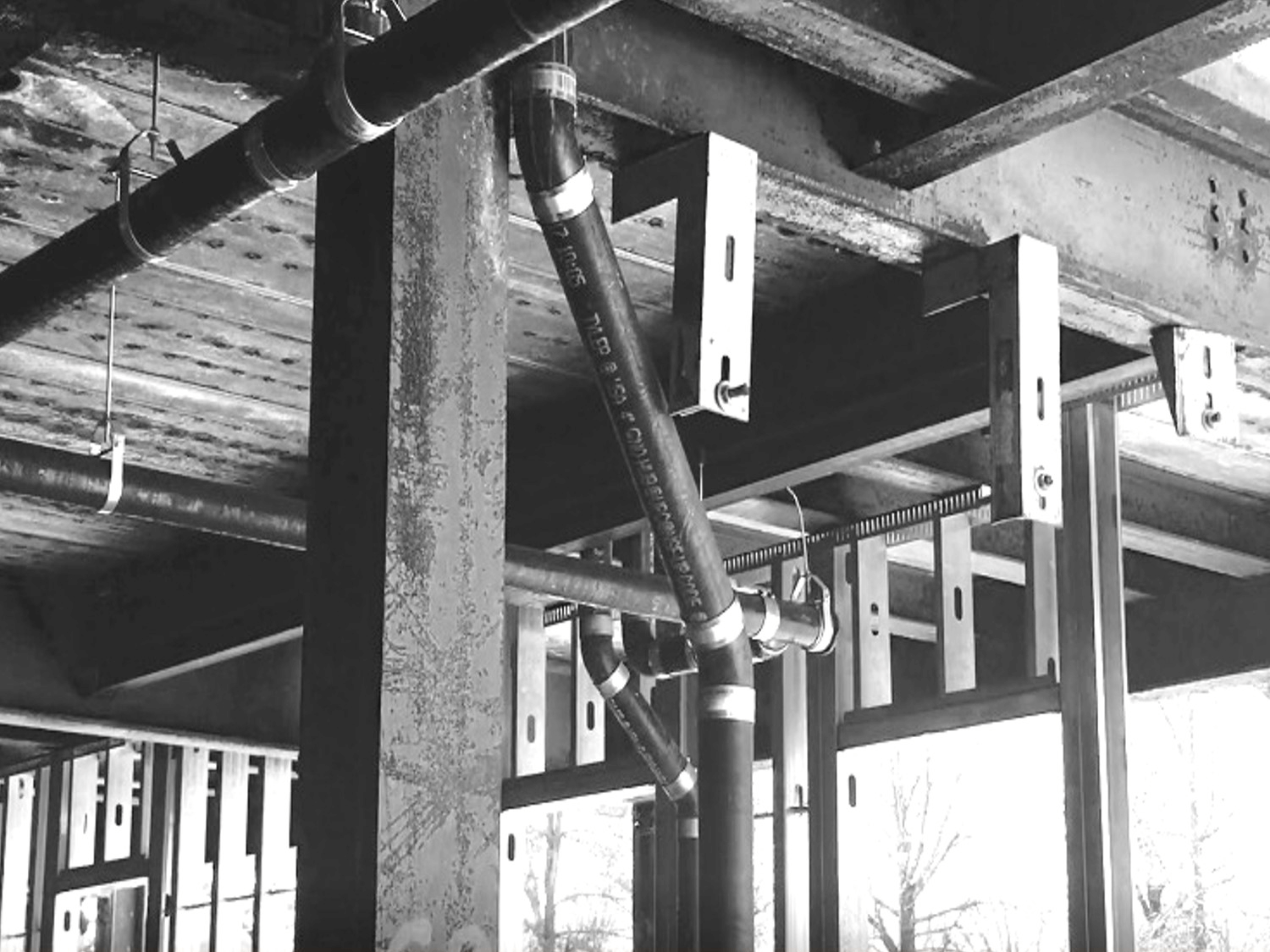

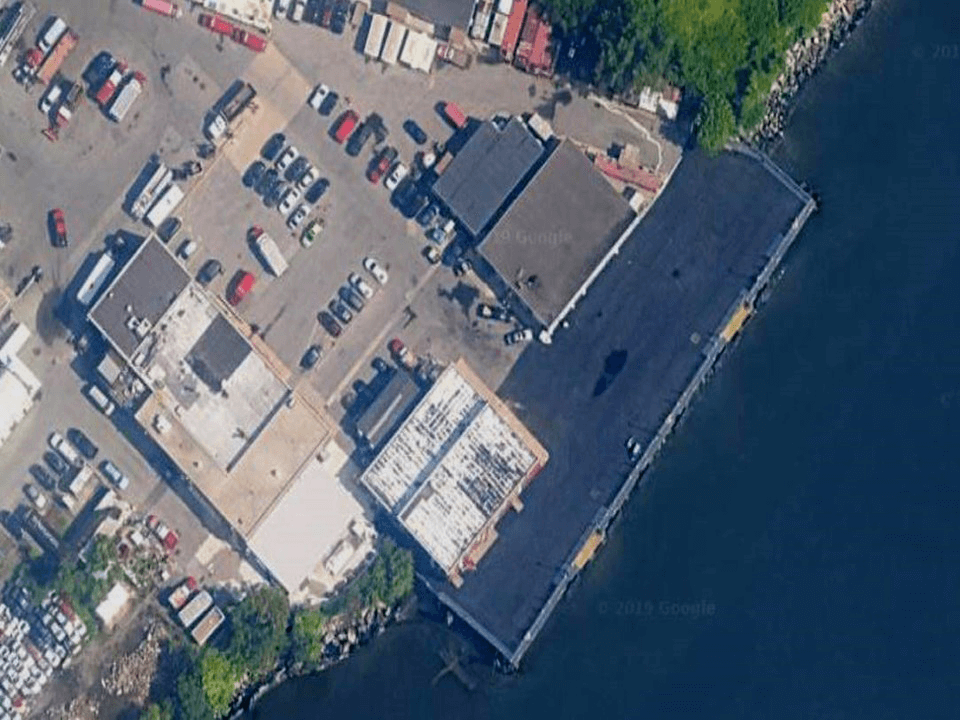

Cameron Engineering provided structural engineering design service for the project which involved rehabilitating and partially reconstructing the FDNY existing concrete-encased steel wharf located at the FDNY Training Academy on Randall’s Island. The wharf is primarily used as a Fire Rescue Boat docking and launching location for water rescues or emergency events. It is secondarily used as a Marine Rescue training area, for materials and equipment deployment, and Hazmat and land-to-ship firefighting training.

The original asphalt was installed directly over the concrete slab without deck waterproofing allowing water, salt, and chemical intrusion. Our innovative design incorporated a liquid-applied, state-of-the-art, bridge deck waterproofing membrane applied to the top of the concrete structure that could be utilized to “flash” the deck, surrounding structures and walkways as well providing a flexible and seamless contiguous system that would prevent potential water infiltration.

The original steel and wooden slat stairs were replaced with aluminum framing with fiber reinforced plastic stair treads and railings. All steel fasteners and support structures were hot-dipped galvanized or aluminum and received a high-performance multi-layer coating system. All new concrete repairs and installations used a high-strength fly ash mix design with intrinsic corrosion inhibiting admixtures.

The design utilized new fender and bollard materials, jacketed the existing caissons, incorporated a new cathodic protection system, removed all sacrificial wood products and ensured all fasteners and support structures were additionally coated with marine grade corrosion resistance products to ensure the wharf system does not readily deteriorate in a saltwater environment. All materials utilized were marine-environment friendly and proven not to negatively impact the surrounding wildlife. The restoration now allows FDNY marine vessels to dock, train and dispatch for emergency operations. FDNY marine vessels have not been able to dock or utilize the structure since 2012.

2021 ACEC NY Engineering Excellence – Silver

Featured Award

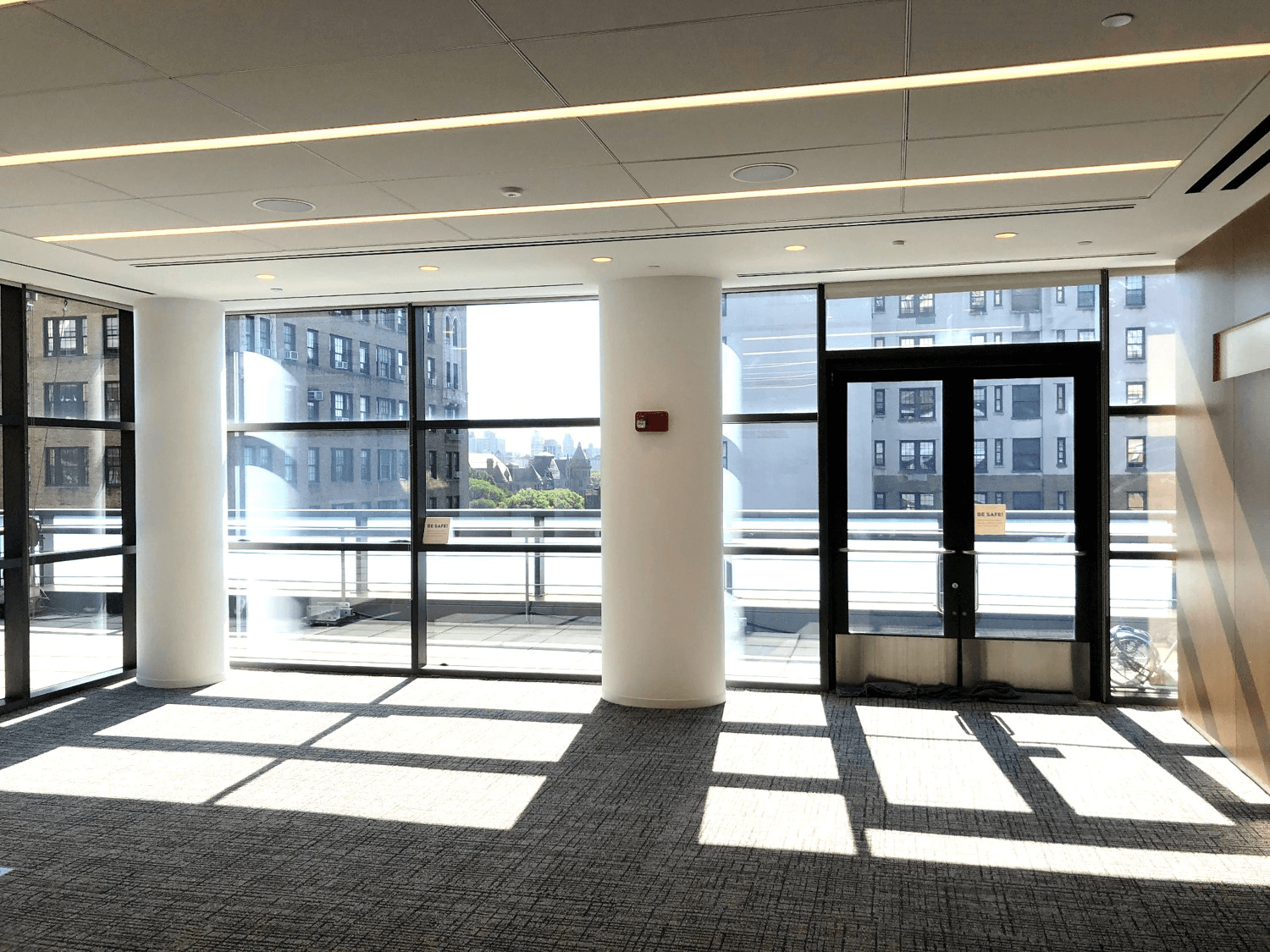

Renovations at The Marlene Meyerson JCC Manhattan

As Engineer of Record, Cameron Engineering provided the design of mechanical, electrical, information technology and audiovisual systems for the renovation of the 7th floor auditorium and build-out. The 7th floor fit-out included upgraded power for the audiovisual components including video conferencing, speakers and the modification of the existing mechanical distribution as well as other support areas.

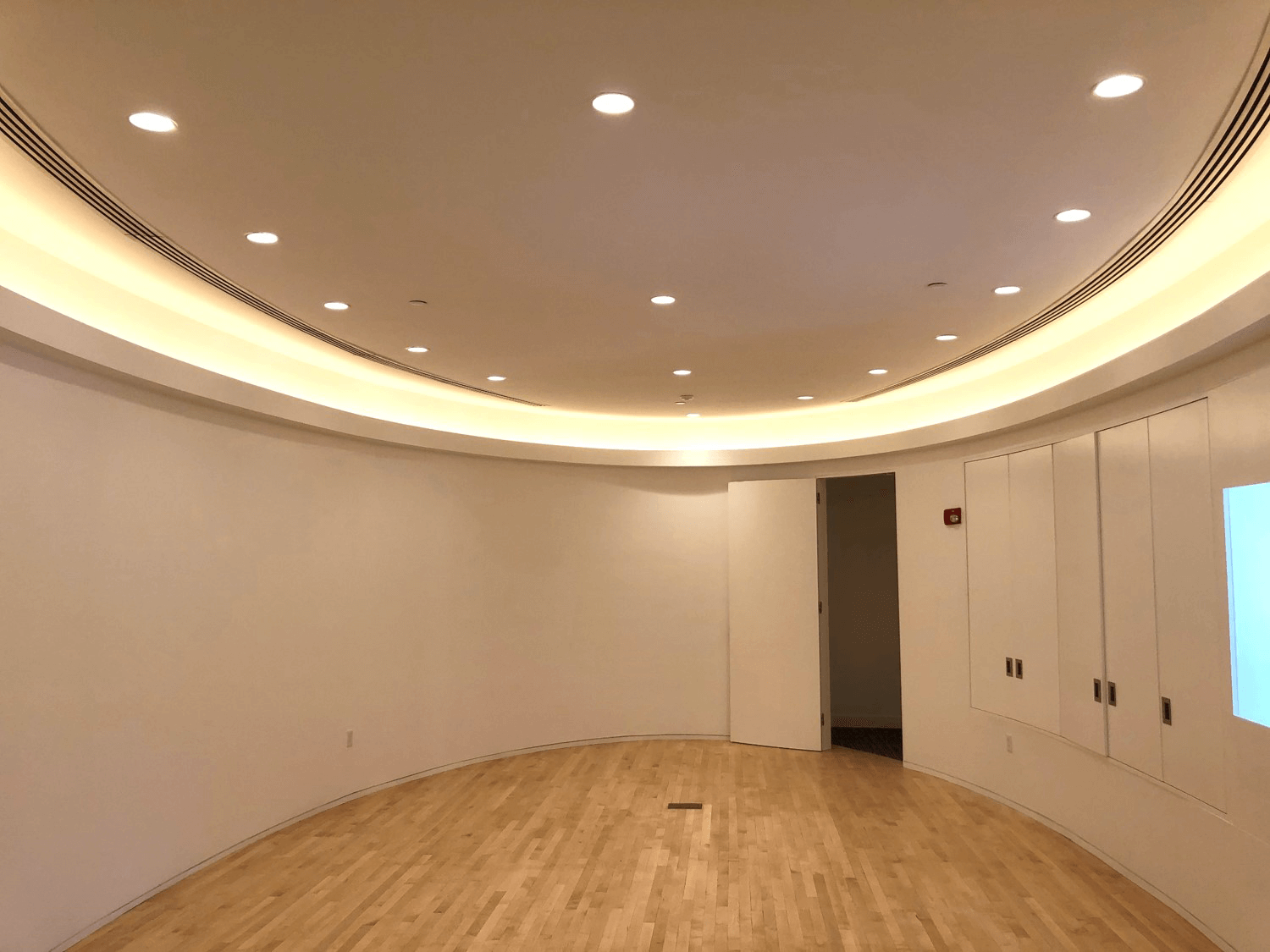

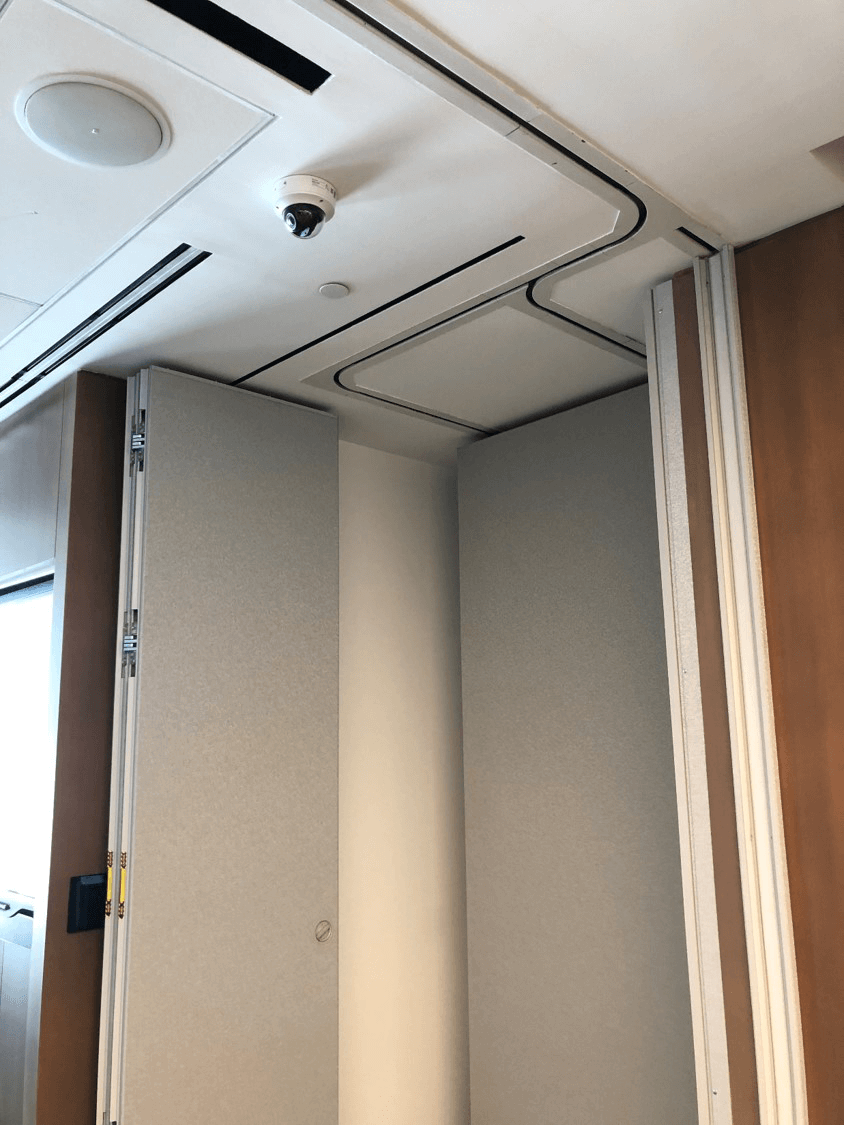

The space is equipped with state-of-the-art Audio/Visual and Lighting Control system. When the motorized shades are raised, the lights will dim automatically to an energy efficient and occupant friendly level by Photosensors placed on the ceilings. There are touch-screen control panels spaced strategically throughout the project site. The AV system has partition sensors for the operable walls that can detect when the room is fully open or when it is closed off.

The public will enjoy the overhead and cove accent lighting in the meditation space as well as the enhanced controls to give the occupants optimal thermal comfort. Users will appreciate that the panels reduce the acoustical reverberation and emissivity from one room to the other.

One of the problems of the site was that the 7th floor has impressive floor-to-ceiling windows allowing a large amount of sunlight to adversely affect the area. Motorized shades were incorporated into the design to allow for near instant mitigation of the sun. When the motorized shades are raised, the lights will dim automatically to an energy efficient and occupant friendly level by Photosensors placed on the ceilings.

The project uses a fully integrated AV system with adaptive inputs from the partition sensors, daylight controls, touch screens and more to provide a wholistic experience for the operator. The overhead and cove accent lighting in the meditation space is both daylit controlled as well as dimmable, to allow the ambiance to be fitting for the activities which will occur within.

Awards 2020

Loeb Boathouse Phase I Improvements at Central Park

2020 ACEC NY Engineering Excellence – Platinum

Complete Building Renovation – Local 14 Operating Engineer’s Headquarters

2020 ACEC NY Engineering Excellence – Gold

Town of Hempstead – Inwood and North Lawrence Zoning Initiative

2020 ACEC NY Engineering Excellence – Gold

Awards 2019

Infrastructure Upgrades to 1407 Broadway

2019 ACEC NY Engineering

Excellence – Gold

Effluent Dechlorination at Long Beach WWTP

2019 ACEC NY Engineering

Excellence – Silver

Awards 2018

FDNY Randall’s Island Water Reclamation Project

2018 ACEC NY Engineering Excellence – Platinum

Clean & Green Biosolids Processing Facility

2018 ACEC NY Engineering Excellence – Platinum

Columbia University Rocco B. Commisso Soccer Stadium

2018 ACEC NY Engineering Excellence – Gold

Awards 2017

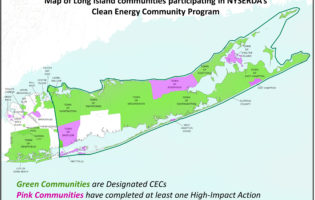

Bay Park Infrastructure Enhancements

2017 ACEC NY Engineering Excellence – Platinum

Awards 2016

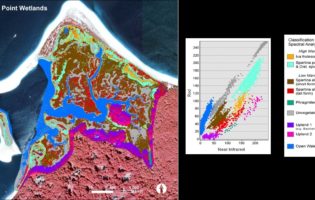

Long Island Tidal Wetlands Trends Analysis

2016 ACEC NY Engineering Excellence – Diamond

Hofstra North Shore-LIJ School of Medicine

2016 ACEC NY Engineering Excellence – Gold

Awards 2015

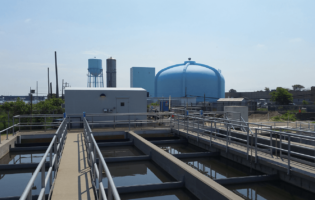

Bergen Point WWTP Effluent UV Disinfection

2015 ACEC NY Engineering Excellence – Gold

Awards 2014

Widex USA, Inc. Corporate Headquarters

2014 ACEC NY Engineering Excellence – Silver

Glen Cove Ferry Terminal and Boat Basin

2014 ACEC NY Engineering Excellence – Diamond

Awards 2013

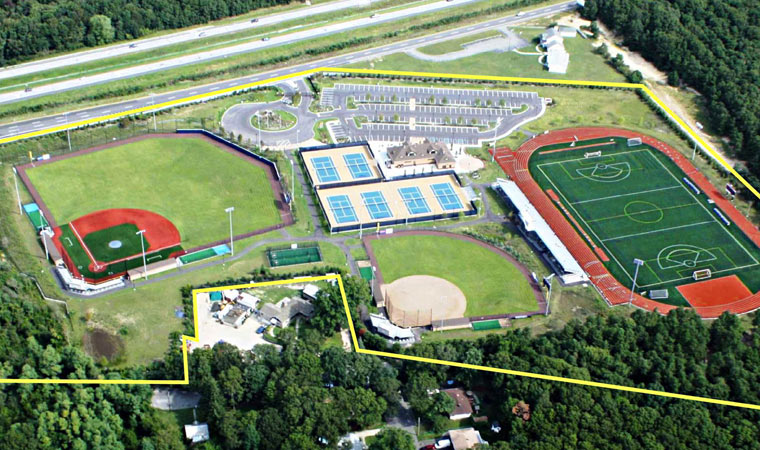

St. Joseph’s College Athletic Complex

2013 ACEC New York Engineering Excellence – Gold

Forge River Watershed Management

2013 ACEC New York Engineering Excellence – Platinum

Town Of North Hempstead Community Center

2013 ACEC New York Engineering Excellence – Platinum

Village of Greenport Water Pollution Control Plant

2013 ACEC New York Engineering Excellence – Platinum

Awards 2012

Awards 2011-2008

Mill Pond Water Quality Improvements

2011 ACEC NY Engineering Excellence – Platinum

Morris County Correctional Facility Security System Upgrade

2010 ACEC NY Engineering Excellence – Silver

Stone Hill at Muttontown: Conservation Easement Planning

2009 ACEC NY Engineering Excellence – Silver

The Ritz-Carlton Residences, Baltimore Inner Harbor, Maryland

2009 ACEC NY Engineering Excellence – Silver

North Shore Hebrew Academy High School Campus

2008 ACEC NY Engineering Excellence – Gold

The Business & Research Center at Garden City

2008 ACEC NY Engineering Excellence – Platinum

Prior Awards

Calverton Camelot – Conservation Subdivision

2007 ACEC NY Engineering Excellence – Silver

Suffolk County Community College Electrical Distribution Systems

2007 ACEC NY Engineering Excellence – Silver

Aircraft Noise Abatement at St. Joachim School

2006 ACEC NY Engineering Excellence – Gold

Harborview Mid-Rise Luxury Condominium Complex

2006 ACEC NY Engineering Excellence – Silver

Massapequa Preserve Streamflow Augmentation & Pond Restoration Study

2005 ACEC NY Engineering Excellence – Silver

Long Beach Parking Facility: MTA – Long Island Rail Road

2005 ACEC NY Engineering Excellence – Gold

Biological Nutrient Removal Retrofit – Glen Cove WPCP

2005 ACEC NY Engineering Excellence – Gold

2005 NYSDEC Environmental Excellence

NYC School Construction Authority – Glen Oaks Campus

2004 ACEC NY Engineering Excellence – Diamond

2004 ACEC National Recognition

Dean G. Skelos Sports Complex, Village of Rockville Centre

2004 ACEC NY Engineering Excellence – Gold

Lido Beach Phase II – Water Main Improvements

2004 ACEC NY Engineering Excellence – Gold

Baxter Pond Restoration

2003 NYACE Engineering Excellence – Platinum

2003 ACEC National Recognition

2003 ASCE Quality Of Life

Arrow Electronics Data Center

2003 NYACE Engineering Excellence – Silver

Bookspan / Doubleday Headquarters

2003 NYACE Engineering Excellence – Silver

Nassau County Fire Service Academy

2002 NYACE Engineering Excellence – Platinum

2002 ACEC National Recognition

Wastewater Treatment Plant Upgrade

2002 NYACE Engineering Excellence – Silver

Municipal Pool Complex at Greis Park

2002 NYACE Engineering Excellence – Silver

NRPA Aquatic Branch

2002 Excellence in Aquatic Award

Nassau County Correctional Facility

2001 NYACE Engineering Excellence – Diamond

Suffolk County Minor League Ball Park

2001 NYACE Engineering Excellence – Platinum

2000 ASCE Civil Engineering Project of the Year

Children’s Interactive Water Play Area

2000 NYACE Engineering Excellence – Gold

Long Beach Waterfront Park

1997 NYSSPE Project of the Year